-

+91-9829026751, +91-9829022851 -

info@calcinedlime.com

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

Preferred Buyer From

| Location | Worldwide |

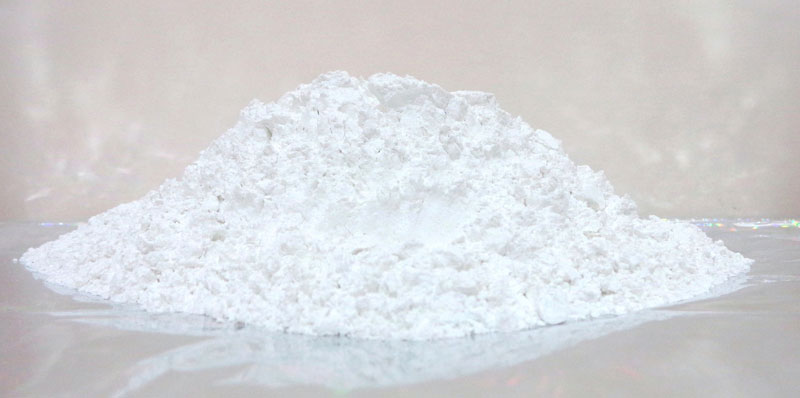

Limestone Powder that we provide is finely processed with the latest manufacturing technologies at the unit. We provide premium Limestone Powder that is quality-tested, and hence widely in demand. Our Limestone Powder is used in industries to carry out numerous applications. Limestone Powder, offered by us, is available at market leading prices.

Chemical Name : calcium carbonate

Chemical Formula : CaCO3

Grades Of Limestone Powder Used In Different Industries :

Composition :

Also Available in Range : Lumps and Chips

Read More...

Chemical Name : calcium carbonate

Chemical Formula : CaCO3

Grades Of Limestone Powder Used In Different Industries :

- Iron & Steel industry : Limestone Lumps are used in this industry both in the blast furnace to lower the temperature of melting and second to from calcium silicate by combining with silica of the iron ore, which comes out as slag. For this purpose, good fluxing Limestone Lumps low in acid constituents such as silica, alumina, sulphur and phosphorus is required. Limestone Lumps should be dense, massive, preferably fine grained, compact and non-fretting on burning.

- Cement industry :

- Limestone containing about 45% CaO and above is usually preferred for the manufacturing of cement.

- Magnesia content in the stone should ideally be less than 3%, although as high as 5% MgO is used by the industry.

- The proportion of AI2O3 + Fe2O3: SiO2should be 1:2:5. Magnesia sulphur and phosphorus are regarding as most undesirable impurities.

- Fertilizers industry : The latest use of Limestone Lumps are introduced in the country is in the manufacture of calcium ammonium fertilizers where Limestone Lumps are used only as carrier. For this purpose, Limestone Lumps must contain MgCO3 + CaCO3 85% (min.) SiO2 5% (max.) and acid in-soluble 14% (max.)

- Glass industry : Glass industry requires Limestone Lumps (CaCO3: 94.5%). Combined CaCO3 and MgCO3 should be 97.5%

- Chemical industry : The calcium carbide manufactures generally prefer lime containing 95% CaO (min.), not more than 3% SiO2, not exceed 2%.

Composition :

- CaCO3 : 85-97%

- CaO : 48-more than 54%

- SiO2 : Below 1%

Also Available in Range : Lumps and Chips